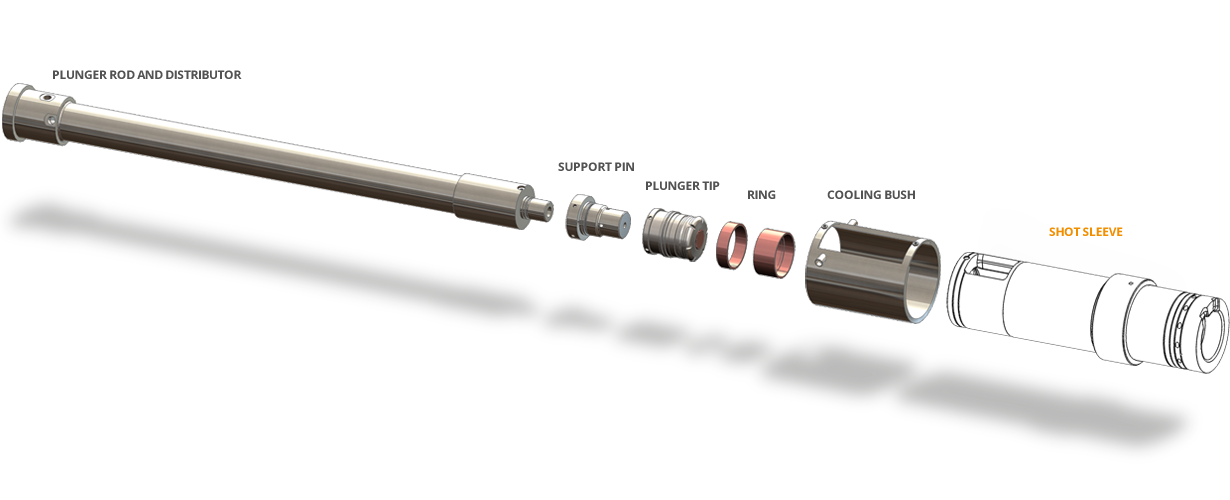

The part of the shot sleeve which is most subjected to erosion is located under the pouring hole, in case this erosion is massive Copromec recommends the use of the interchangeable bush. Once the lifetime of the bush is over, it can be easily replaced, avoiding the purchase of a new shot sleeve.

The part of the shot sleeve which is most subjected to erosion is located under the pouring hole, in case this erosion is massive Copromec recommends the use of the interchangeable bush. Once the lifetime of the bush is over, it can be easily replaced, avoiding the purchase of a new shot sleeve.