In the aluminum and magnesium high pressure die casting market, Copromec offers the best injection systems operating on cold chamber high pressure die casting machines solution. Copromec supplies patented ringed plunger tips, lubricated rods, thermoregulated shot sleeves, lubricants, and much more.

Thanks to our over twenty years of experience we have reached an excellent quality level that allows us to be competitive worldwide and recognized by the main car manufacturers. The main goal achieved by our customers is the optimization of their production process, which comes from the reduction of maintenance costs, the improvement of casting quality, the extension of component lifetime, the reduction of machine downtime, and the reduction of cycle time.

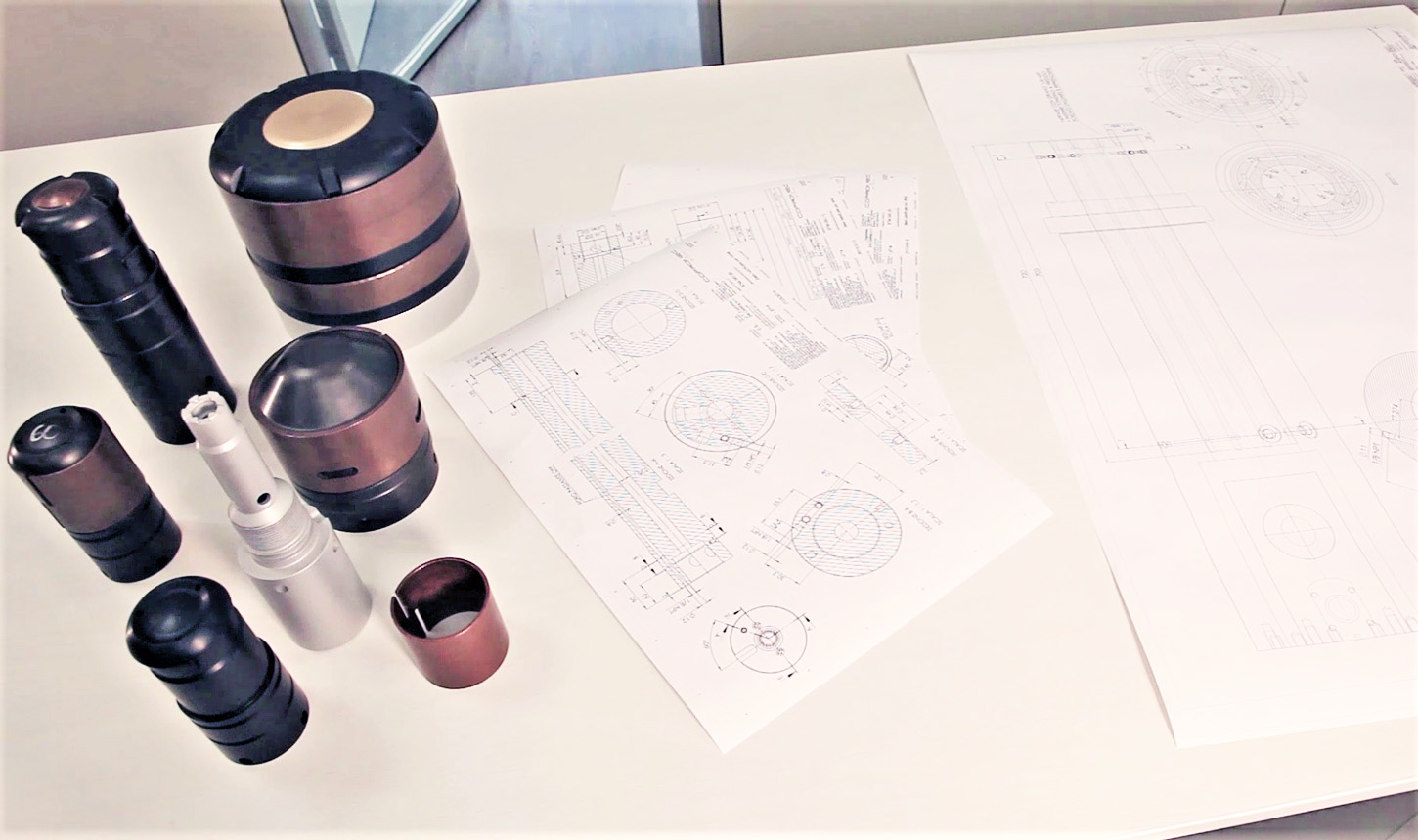

After analising the injection system and the different processes used by the customer, our engineering department suggests the most suitable solution. Using latest generation softwares, we carefully design customised components, that will be assembled on the customer's die-casting machine.

We use only certified high-quality raw materials to make shot rods, shot sleeves, plunger tips, and supports. Each component is subjected to a series of heat and surface treatments that guarantee high-quality standards of the final product. Copromec workshop is equipped with technologically advanced machinery such as drilling machines, milling machines / machining centers, and CNC lathes.

Once the production phase is completed, the product is shipped to the customer, where it is assembled on the machine, with the support of one of our technicians. After the installation is completed, the customer can still contact Copromec technical support, should he need assistance or guidance in making the most of Copromec products.

Our process management system is certified according to ISO 9001: 2015 quality standard

LOOK AT THE CERTIFICATE